Sheet Lining is intended to withstand corrosion of reactive fluids. It possesses an exceptional combination of non-stick, thermal and chemical properties coupled with mechanical durability.

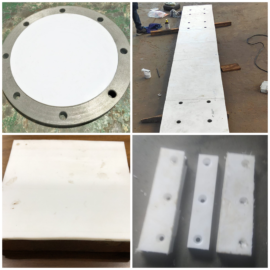

Sheet Lining: Sheet linings prove to be an excellent way of corrosion protection and also prevent products with high purity from getting contaminated. Sheet lining also resists abrasion to the base material by creating a coating of a different material. Here, the extensive properties of fluoropolymers come into use. Sheet lining using fluoropolymers possesses an outstanding blend of thermal, chemical, and non-stick properties combined with its mechanical durability. The fluoropolymers we use for sheet lining are PTFE, PFA, FEP, PP and ETFE. We provide two types of sheet linings –

- Bonded Sheet Lining (the sheet is bonded to metal with the help of an adhesive & joints are thereby thermo-welded together) and

- Loose Sheet Lining (the sheet is welded together and inserted into metal equipment without bonding).

Some benefits of sheet lining that make it a popular method are resistance to permeation, more economical, maintains purity at per billion levels and more durable than thermoset resins.

| Lining Material | Thickness |

| PFA | up to 4 mm* |

| FEP | |

| PTFE | |

| ETFE | |

| PVDF | |

| PP | |

| Material | Our standard usage of raw materials is Gujarat Fluorochemcials Limited (Inoflon), 3M (Dyneon), Itaflon S.R.L. (Itaflon), Daikin (Polyflon), and HaloPolymers (Fluoroplast). We can also offer other special grades as per requirements. |

| Applications (Industries) | · Chemical · Pharmaceuticals · Electrical · Electronics and Communications · Fertilizers · Pesticides · Petrochemicals · Nuclear Power · Oil Exploration · Food Processing · Defence · Aerospace and more |